Basic Facts on How Arrow Cements Work

- Arrow plastic pipe solvent cements work by solvent action.

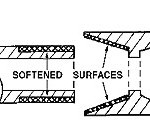

- When cement is applied, solvent action softens (dissolves) the pipe and fitting surfaces, preparing them for joining. (See Fig. 2)

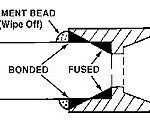

- A few seconds after joining, the interference section fuses together. The non-interference section is bonded together. (See Fig. 3)

- The joint cures by evaporation of the cement solvents. If possible, allow 24 hours before pressure testing – longer in cold weather.

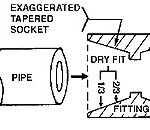

- Figure 1

- Figure 2

- Figure 3

Important Points for Trouble-Free Use

Interference Fit

- Required for proper solvent action.

- 1/3 to 2/3 dry fit is best. (See Figure 1) ‘Dry fit’ is without cement.

- If pipe fully inserts in fitting, it should be snug. Avoid loose fits.

Pipe Cut

- Cut pipe square and remove burrs to avoid leaks.

Proper Cleaning

- Remove all dirt, oil, moisture and surface gloss for best results.

- Arrow 901 Cleaner can be applied to non-pressure systems and ABS pipe/fittings.

Apply Primer

- Vigorously apply Primer to PVC and CPVC pipe/fittings.

Proper Cement

- Check that cement is recommended for pipe type, diameter, application and for use in your specific working conditions.

- Make sure cement is free-flowing and not gelled.

Apply Cement

- Apply a heavy coat of cement to pipe, a light coat to fitting socket and another coat to pipe.

Join Pipe & Fitting

- Use a slight twisting motion to insert pipe into fitting until it bottoms and hold for a few seconds to prevent pipe from pushing out.

- A joint should fuse (‘Grab’) shortly after joining pipe and fitting. If not, avoid using as it may pull out or leak.

Cement Bead

- A cement bead will appear at pipe/fitting interface if enough cement was used.

- Wipe off bead to speed joint curing.

Curing

- Allow sufficient curing time (24 hours is best) to assure a strong joint.